Micro Cement Flooring

Luxury Micro Cement Flooring for Modern Interiors

Micro cement flooring is a decorative, cement-based coating that allows you to renovate floors and walls without major construction or demolition. With a thickness less than 3 mm.

Its ability to be applied directly over existing surfaces without the need for demolition makes it a perfect choice among different types of floor finishes for interior designers, especially when compared to other seamless solutions like Terrazzo Flooring and Resin Flooring.

Micro cement Flooring

Stone-Like Texture with High Durability

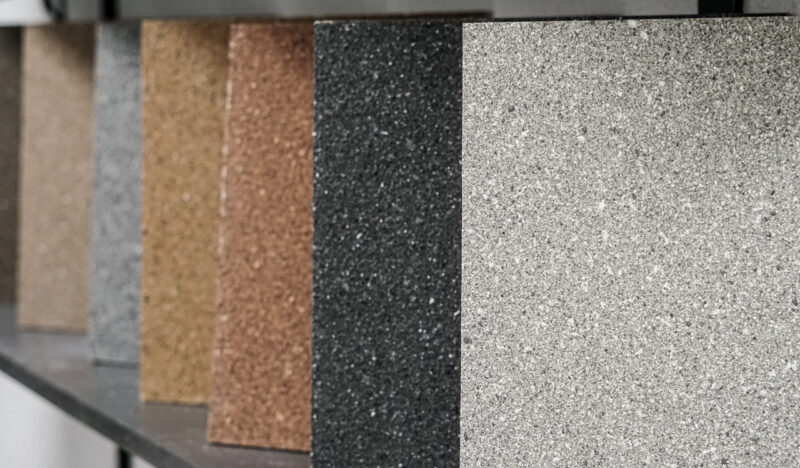

It is a combination of concrete and sand to create a textured surface that looks more like stone than the typical concrete finish.

Micro cement flooring is also characterized by adding a surface texture that resembles the surface of natural stone. Although it is made from an artificial material, the texture of microcement creates a beautifully authentic look for a floor.

Apart from the aesthetic finish, microcement on floors stands out for its functionality. It is resistant to traffic, scratches, and the effects of sunlight and impacts. All of this makes the micro cement flooring a perfect choice for commercial businesses, where minimalism, durability, and seamless aesthetics are priorities.

Types of

Micro Cement Flooring

If there is one particularity that perfectly defines microcement for floors, it’s versatility, as there are different types depending on the texture and finish you want to upgrade your space with. At Color Lab, we have up to 3 different micro cement systems, each of which adapts to specific needs and finishes.

Micro cement with aggregates

This type of micro cement involves aggregates such as marble and quartz, all of which add depth and texture to floor.

Micro cement with fine aggregates

Micro cement flooring without aggregates is the ultimate choice for those seeking sleek and polished look. It offers a smooth and aesthetic style.

Micro cement for wet areas

Blending aesthetics with functionality, micro cement for wet areas offers a waterproofing and slip resistance, making it a good idea to micro cement flooring in bathrooms and kitchens.

Advantages Of Micro Cement Flooring?

Trusted by interior designers

Frequently recommended by top interior designers for its aesthetic flexibility and ability to blend into any modern decor theme.

Seamless finish without expansion joints

It is a continuous pavement, which means that there are no expansion joints or unions. The entire floor renovation is done in one step.

Direct application over existing floors

It adheres to any type of material without the need to remove the existing support. This results in saving more costs and renovation time

Durable and long-lasting

Microcement flooring is highly resistant to high traffic, abrasion, and to household cleaning products, making it durable for daily use.

Custom designs and unique finishes

No two micro cement floors are alike. As it offers wide range of custom color tones, textures, and finishes

Ideal for wet areas

Micro cement flooring provides a water-resistant, and stylish finish, making it ideal for shower rooms or any internal wet areas.

Ultra-thin application

The microcement floor does not raise the floor level too much, this is due to its minimum thickness that ranges between 2 and 3 mm.

Explore Our Step by Step Micro Cement Application Process!

01.

Clean the future microcement floor

We begin by thoroughly cleaning the surface to remove dust, stains, grease, or any other particles and ensure a flawless base for micro cement application. It is very important to check the degree of humidity of the pavement, it will be necessary to wait for it to dry or directly apply Our Special Water Base Protection Barrier to block rising damp and act as a vapor barrier.

02.

Primer

Once the surface is clean, we apply a layer of primer on the pavement to enhance the adhesion between the existing support and the new microcement floor.

03.

First layer of microcement base

After the primer, we place the first layer of unpigmented micro cement base. It is advisable to use a fiberglass mesh, as it will prevent the future cracks. Once applied, we sand the surface for a smooth finish.

04.

Second layer of microcement base

Once the surface is completely dry, apply a second coat of pigmented microcement base. In this step, the desired microcement color will be chosen to cover the continuous pavement and, once the surface is perfectly covered, the microcement floor will be sanded.

05.

Two layers of finishing microcement

The fifth step involves applying two layers of finishing microcement or finish with pigment. Depending on the finish and the degree of slipperiness sought, medium or coarse microcement can be used.

- For interiors we recommend two coats of Microdeck, for a sleek and durable finish

- For exteriors, we recommend two layers of Microstone as it offers enhanced durability

06.

Protection of microcement floor

The last step of applying microcement to the floor is one of the most important. Finally the surface is sealed for durability and resistance. We apply Special Colorless Coating Water Base.

This protects your floor against moisture, stains, and wear. While also, allowing for waterproofing and anti-slip finishes when needed.

Tips to avoid micro cement flooring problems

1

Ensure proper ventilation in the first few days after application to allow the floor to cure properly.

2

Avoid walking on floor for at least 7

days after application

3

Avoid moving furniture or machinery across the floor until it is fully cured

Following these steps, you’ll make sure that the floor sets correctly and maintain its quality over time.

Ready to Upgrade Your Floors with Seamless Micro Cement Finishes?

Transform your space with durable, modern flooring that reflects your design vision.

Exceptional customer service

From the first consultation to post-installation guidance, our team ensures a smooth and satisfying experience for every client.

World-class floors materials

we provide high-end flooring materials sourced from premiere manufacturers specialized in construction and finishing materials.

Wide range of floor options

we offer different types of floor finishes and materials to suit our clients different budget and requirements, and bring the highest value to your spaces.

View Our Projects

Include latest micro cement projects for Color Lab

FAQS

Yes, Microcement is an excellent choice for flooring due to its durability, versatility, waterproof properties and low maintenance requirements. It can be customized to match any design aesthetic and is suitable for both residential and commercial spaces.

Yes, one of the advantages of microcement flooring is that it can be repaired if damaged. The process involves cleaning the area, applying a new layer of microcement, and resealing the surface. This makes microcement a practical and long-lasting flooring solution.

Microcement flooring is known for its durability and longevity. When properly installed and maintained, it can last for many years, typically ranging from 10 to 20 years or even longer. The lifespan of microcement flooring depends on factors such as installation quality, foot traffic levels, regular maintenance, and overall usage.

Yes, it’s water-resistant and can be modified to be anti-slippery, making it a good choice for bathrooms and kitchens flooring.

The micro cement flooring smooth finish doesn’t mean that it has to be slippery. This finish can be adjusted during the application process to be slip-resistant, making it safe for all types of environments.