Description

Files To Download:

Technical Data Sheet

Hygienic Certificate

Data Sheet

FAIR FARBA PHOTOCAL PHOTOCAL IN POWERS OF:

VIRUSSERMALS, TERMOREFLELEKSY, ANTYSMOGOWY, COVERS FOR THE INTRUCTIONS

CONDITION:

Water-based silicate (silicate) paint designed for painting building elements both inside and outside the rooms. It can be used for a variety of building materials, such as: mineral and polymer plasters perennial (e.g. acrylic), concrete, brick walls. Creates a homogeneous, well-covering, waterproof, matte, snow-white coating (white version) or the right color. TITANIUM FA is a technologically advanced paint with photocatalytic, thermal insulation and thermoreflex properties. Thanks to the use of the microsphere composite, the paint has a very high ability to reflect heat in winter – it retains heat in the winter and reduces the heating of rooms in the summer. Two functions, photocatalytic and thermoreflective (thermoleisolation) were combined in one paint. The paint protects the exterior walls of buildings from moisture absorption. After drying, it gives a durable, hydrophobic layer, with very good adhesion to typical mineral substrates. It creates a layer characterized by very high vapour permeability, ensuring free penetration of water vapor and moisture removal through the surface on which it was applied. It is resistant to washing and atmospheric factors. It contains acrylic binder and potassium water glass and modifying additives, pigments and mineral fillers, as well as measures to prevent the development of fungi and mold on the surface of the facade.

It is produced in the basic white color, however, on request it can be dyed high-quality pigments for a number of pastel colors.

PHOTOTHIC AND TERMOREFLEXYAL PROPERTIES:

The paint contains a composite with photocatalytic and thermoreflective (thermolemy) properties, which is a combination of relatively large silicate microspheres with a photoactive catalyst.

The product is effective in removing gaseous pollutants of the urban and industrial type such as: tobacco smoke, sulphur dioxide, carbon monoxide (casium), nitrogen oxides, aldehyde asses, alcohols (methanol, ethanol, isopropanol), aromatic and aliphatic hydrocarbons (benzene, toluene, ethylbenzene, xylene, kerosene, bench). As a result of the photocatalytic process, occurring in the presence of light and oxygen (contained in the air), atmospheric pollution, when contacted with painted surfaces, oxidize, transforming into substances harmless to health and the environment. The larger the surface is covered with photocatalytic paint, the faster they are removed from the environment. In the face of the catalyst (contained in paint), discoloration is also purified on the surfaces of the walls, e.g. nicotine stains. The phenomenon occurs using direct, reflected, diffuse light both solar and artificial. In the case of insufficient natural lighting, in order to maximize the effect of the paint, it is advisable to install illumination. Moisture contained in the air (e.g. indoors) is enough for the course of the process. The composite present in the paint gives the paint the ability to eliminate more than 90 % of the thermal energy from the infrared (heat) radiation to its surface, lowering the heat transfer coefficient and helping to save heat during the winter. Studies have confirmed that the paint effectively insulates the walls of buildings that are covered with it reflect heat radiation. This extraordinary property is due to the microspheres, thanks to which the paint intelligently reacts to the changing temperature inside and outside the room. Microspheres are small particles with spherical shapes, inside which there is an inert gas. This ensures excellent radiation reflection. Thanks to this, the room keeps the room warm on cold days, and on hot – it does not heat up.

PREPARATION OF SURFACE AND USE:

It is a ready-to-use paint. Under no circumstances should you add chalk, lime and dry adhesive paints or other materials. It is not recommended to paint surfaces covered with lime paint. Surfaces before painting should be cleaned, dried, removed loose parts and degreased. Adhesive and lime-melting paints absolutely remove. Surfaces not painted or very old are recommended to prime the GRUNDER SK substitutes from Pigment. Fresh cement-lime plaster can be painted no earlier than 4 weeks after application. It is allowed to paint after three days of shaded mineral plasters used in the insulation systems of buildings, when the temperature on these days remains above +15oC. Loss and cracks to replenish – cement mortar. Before painting, mix the paint thoroughly. The paint can be applied once or twice, depending on the absorbency and structure of the substrate. The next layer can be applied after the previous one (after a minimum of 12 hours), using the method “for the cross” and maintaining one application direction for a given layer. Technological breaks and joinings should be planned in advance, for example: in corners and building refractions, under the drain pipes, at the junction of colors, etc., so that they are located in invisible places. Wash the tools with water immediately after the work is completed.

ADDITIONAL INFORMATION:

The best results can be obtained using the spray method. With traditional painting methods (rolling, brush), with the wrong choice of tool, technique of painting and adverse conditions (temperature and relative humidity of air), it is possible to appear streaks in some colors. The individual grays of the product after coloring may differ slightly in the shade of some colors available in the computer coloring system. In order to avoid noticeable differences, it is necessary to make an area constituting a separate architectural whole, in one working cycle, products from the same production batch. If it is necessary to use products from different production batches, it is recommended to mix them together in order to unify the shade. Possible amendments should be made using the ‘wet to wet’ method. Before starting painting with paint, it is pleasing to check the color in all packages with the order placed.

NOTES:

In order to avoid differences in shades of colors, it is necessary to apply paint on one surface from the same production date. Painting surfaces that differ in texture and technical parameters can cause the effect of different shades of a given paint color. Covering objects, windows and equipment from starting work, especially glass, ceramics, natural stone, metal and clinker. The alkaline product. During work, you should wear clothing, gloves and glasses. Due to the various technologies and raw materials used in the products by other manufacturers, the manufacturer is not responsible for the effects of mixing his product with other products. If white paint is dyed with the pigments of other manufacturers, it is always necessary to carry out a test for a smaller amount. The paint should be stored in the original and sealed packaging.

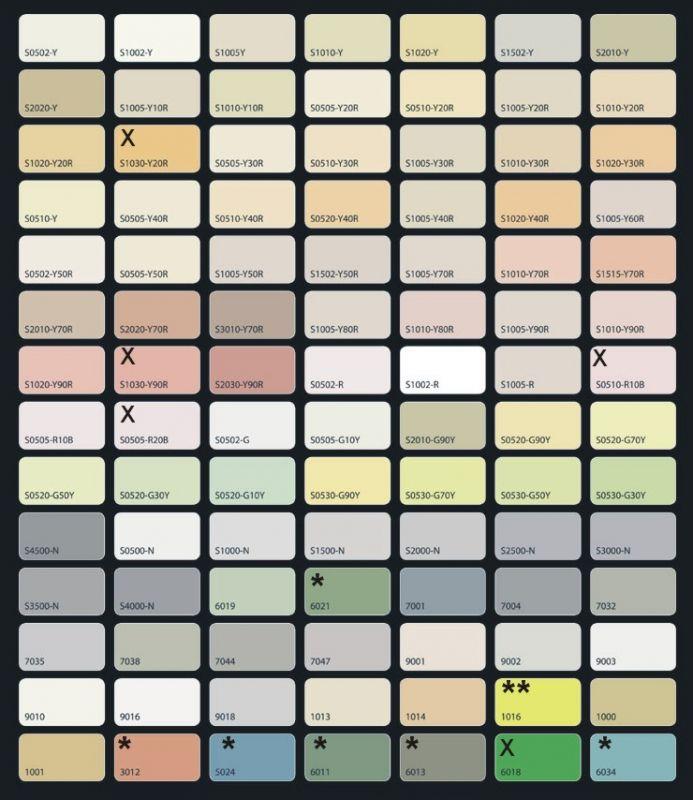

EXAMPLE PALET OF BARW:

Colours marked (?) available after agreement, with a minimum of 100 L,

Colours marked (?) available upon agreement, at least 200 L,

Colors marked (X) temporarily unavailable.

TECHNICAL SPECIFICATIONS:

- Available colors: white, custom-made selected colors according to NCS or RAL cards

- Coating: Mineral mat

- Paint: roller, brush or after proper spray dilution

- Apply and store at a temperature: 5x25oC

- density according to PN-82/C-81551: approx. 1,5 g/cm3

- Applying another layer, 20oC, air hp 50%: after 12 hours.

- Viscosity Brookfield 20x2oC, according to PN-ISO 2555: 10000×15000 mPa?s

- pH value according to PN-C-04963: 11-12

- fixed part content PN-EN ISO 3251: 53,0×55,0 % weight

- Drying time at 23×2 C, PN-C-81519:12 h

- Recommended Wet Coating Thickness PN-EN ISO 2808: 90-100 ?m

- The largest grain size (granulation), PN-EN 13300: small to 100 m

- Recommended number of layers: 2, for some colors: 3

- capacity: 8-10 m2/L

- Equipment washing and dilution: water

- Certificate: Hygienic

- Standard: PN-C-81913:1998

- Warranty: 12 months from the date of manufacture (placed on the lid)

- Packages: 5 L; 10 L

Reviews

There are no reviews yet.