Description

Files To Download:

Technical Data Sheet

Hygienic Certificate

Data Sheet

INTRODUCTION FARBA OF PHOTOCABLE IN POWERS:

INDUSTRY, ANTIALERGISTE, TERMOREFLEXY, ANTYSMOGOWYS

CONDITION:

Water-based paint designed for painting the surfaces of walls and ceilings inside the rooms. It creates a wash-resistant, well-covering, deep matte coating permeable to couples and gases (diffusion, “breathing” of the walls). TITANIUM IN is a technologically advanced paint with photocatalytic, thermal insulation and thermoreflex properties. Thanks to the use of the microsphere composite, the paint has a very high ability to reflect heat in winter – it retains heat in the winter and reduces the heating of rooms in the summer. Two functions, photocatalytic and thermoreflective (thermoleisolation) were combined in one paint.

It can be used for a variety of building materials, such as: mineral and polymer plasters (e.g. acrylic), concrete, bricks, gypsum, paper wallpapers. The indoor surfaces give an aesthetic and durable look. The slightly soiled surface of the paint can be washed with a slightly damp cloth or sponge. It is based on aqueous polymer dispersion with the addition of pigments, mineral fillers, synthetic and refining agents. It contains a photoactive catalyst. It is produced in the basic white color, however, on request it can be dyed high-quality pigments for a number of pastel colors.

PHOTOTHIC AND TERMOREFLEXYAL PROPERTIES:

The paint contains a composite with photocatalytic and thermoreflective (thermolemy) properties, which is a combination of relatively large silicate microspheres with a photoactive catalyst.

The product is effective in removing gaseous pollutants of the urban and industrial type such as: tobacco smoke, sulphur dioxide, carbon monoxide (casium), nitrogen oxides, aldehyde asses, alcohols (methanol, ethanol, isopropanol), aromatic and aliphatic hydrocarbons (benzene, toluene, ethylbenzene, xylene, kerosene, bench).

As a result of the photocatalytic process, occurring in the presence of light and oxygen (contained in the air), atmospheric pollution, when contacted with painted surfaces, oxidize, transforming into substances harmless to health and the environment. The larger the surface is covered with photocatalytic paint, the faster they are removed from the environment. In the face of the catalyst (contained in paint), discoloration is also purified on the surfaces of the walls, e.g. nicotine stains. The phenomenon occurs using direct, reflected, diffuse light both solar and artificial. In the case of insufficient natural lighting, in order to maximize the effect of the paint, it is advisable to install illumination. Moisture contained in the air (e.g. indoors) is enough for the course of the process. The composite present in the paint gives the paint the ability to eliminate more than 90 % of the thermal energy from the infrared (heat) radiation to its surface, lowering the heat transfer coefficient and helping to save heat during the winter. Studies have confirmed that the paint effectively insulates the walls of buildings that are covered with it reflect heat radiation. This extraordinary property is due to the microspheres, thanks to which the paint intelligently reacts to the changing temperature inside and outside the room. Microspheres are small particles with spherical shapes, inside which there is an inert gas. This ensures excellent radiation reflection. Thanks to this, the room keeps the room warm on cold days, and on hot – it does not heat up.

PREPARATION OF SURFACE AND USE:

The paint after mixing is ready for use, only in the case of thickening can be added to 5% water. The surface designed for painting should be thoroughly cleaned, remove loose paint lobes, degrease. Old coatings of adhesive and lime paints should be removed. Fresh cement-lime plaster can be painted no earlier than 4 weeks after application. Smooth surfaces to grind with sandpaper. Loss and cracks are replenished with FILLER or BIEL-PUTZ, with a larger -give. The substrate should be primed with BIEL-GRUNT / SIL-GRUNT or universal FARBA DMSC.

ADDITIONAL INFORMATION:

The individual grays of the product after coloring may differ slightly in the shade of some colors available in the computer coloring system. In order to avoid noticeable differences, it is necessary to make an area constituting a separate architectural whole, in one working cycle, products from the same production batch.

If it is necessary to use products from different production batches, it is recommended to mix them together in order to unify the shade. Possible amendments should be made using the ‘wet to wet’ method.

NOTES:

Due to the various technologies and raw materials used in the products by other manufacturers, the manufacturer is not responsible for the effects of mixing his product with other products. If white paint is dyed with the pigments of other manufacturers, it is always necessary to carry out a test for a smaller amount. The paint should be stored in the original and sealed packaging.

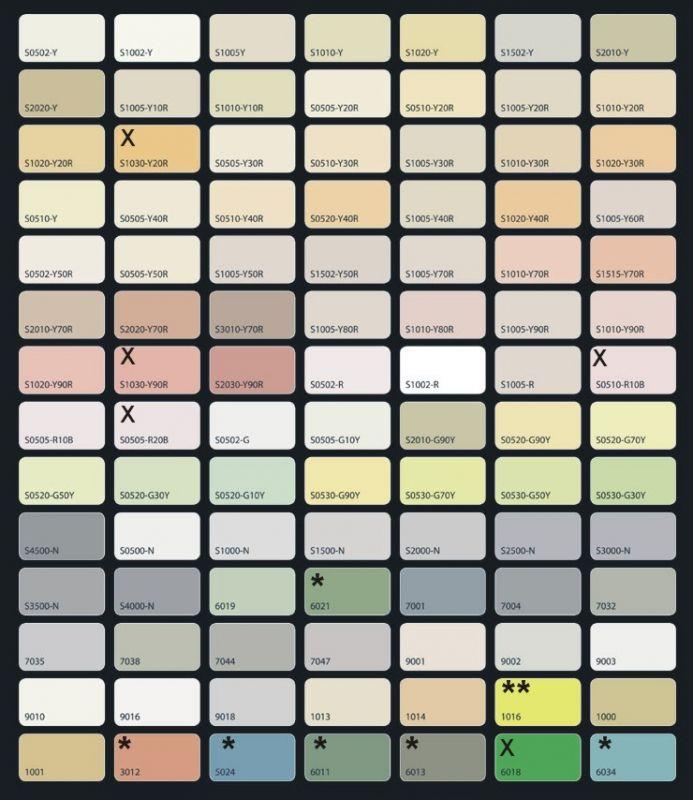

EXAMPLE PALET OF BARW:

TECHNICAL SPECIFICATIONS:

- Available colors: white, custom-made selected colors according to NCS or RAL cards

- Coating: matte

- Scrubbing resistance class: 1 according to PN-EN 13300

- Paint: roller, brush or after proper spray dilution

- Apply and store at a temperature: 5x25oC

- density according to PN-82/C-81551: approx. 1,40 g/cm3

- Applying another layer, 20oC, air number 50%: after 4 hours

- Viscosity of Brookfield 20x2oC, according to PN-ISO 2555: 12000 x 16000 mPa?s

- pH value according to PN-C-04963: 8.0-9.5

- Drying time at 23×2 C, PN-C-81519: 2 hours

- Recommended Wet Coating Thickness PN-EN ISO 2808: 90-100 ?m

- The largest grain size (granulation), PN-EN 13300: small to 100 m

- Paraque remediation coefficient: medium 15 15 ?V x 150 g/(m2 x 24 h); 0.14 x sd x 1.4 m

- Recommended number of layers: 2, for some colors: 3

- capacity: 10-12 m2/L

- Washing of equipment and dilution: water

- Certificate: Hygienic

- Standard: PN-EN 13300

- Warranty: 12 months from the date of production (placed on the lid)

- Packages: 5 L; 10 L

Reviews

There are no reviews yet.